In Pederobba, in the province of Treviso, Consuelo Muredda designs and programs printing machines with technologies highly valued on the market and in the fashion industry. Using a one-of-a-kind self-produced ink, suitable for both hard and flexible materials

As in any other field of human endeavour, the most important (and most difficult) thing about doing business is finding a good idea. The right idea can move mountains, make the most visionary fantasies a reality or, steering the conversation toward themes PTE holds dear, print a pattern on a fabric. Even off scale, in such a way as to make it look like a work of craftsmanship rather than the result of an industrial process.

This is what Consuelo Muredda, owner of Finitech Italia, the Pederobba-based digital printing solutions specialist, has managed to do. Initially, very few people gave her credit for the option of printing objects at greater heights than was normal at the time: “I remember well”, says Muredda, “seven years ago, when Finitech had just begun, an exhibitor at a specialist trade fair reacted with scepticism, actually with a loud laugh, at my intention of being able to print directly on a substantially sized box”. Consuelo Muredda welcomed it as a challenge, one of the many she has always taken as motivation, right from the first start-up launched by the then 18-year-old Industrial Design student, trying in vain to get a dozen colleagues from Milan’s Polytechnic involved in a project that was completely innovative for the time (“...they were hesitant”, the manager recalls, “we were young and needed money; but I had a dream and little desire to give up. I went on alone.”), up to directing Finitech Italia, a company that does not deny its intention to expand internationally, as suggested by the “Italy” affixed to the company name.

“The successful idea”, explains Muredda, “was transforming printers from plotters to complete flatbeds, with a printer arm on a fixed plane and a built-in rotary option: a very delicate operation as this re-functionalisation absolutely had to be done without sacrificing precision. Through carefully selected components and, specifically, German-made belts and worm screws, even this obstacle could also be overcome.

Far from resting on her laurels, the Finitech Italia manager carefully observes the evolution of printing technologies and, with the advent of UV machines, she ventured into a new project: creating her own inks. “The advantage is twofold”, points out Consuelo Muredda, “by producing them ourselves we are fully aware of what is in them, whereas third party inks are often extremely malodorous... to tell the truth, we had to add a slightly odorous component only for legislation then banned them due to the risk of someone drinking them. Secondly, we can develop our own studies to adapt to market and environmental demands: for instance, our UV inks are water-based, plus its new formula allows us to print on both rigid and flexible surfaces using a single product, from mirrors to leather to tyres. We have created formulas that are compatible with each other, i.e., changing between our different ink types (rigid, hybrid or flexible) does not call for machine washing, which, for customers, translates into saving on time, money and consumption.”

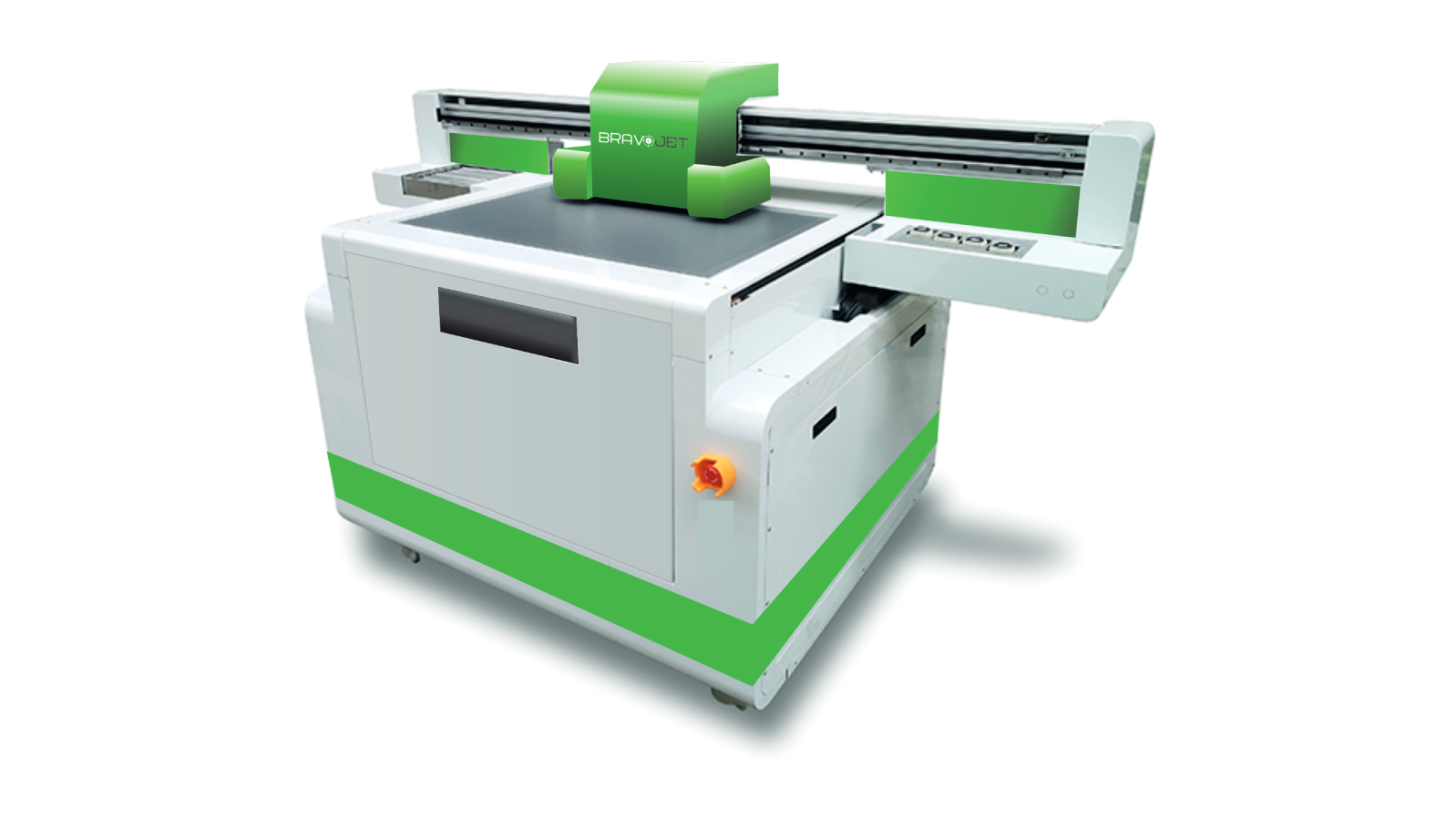

In terms of machines, Finitech's know-how translates into the Bravo-jet models among others, designed by Muredda herself (who also programs the software) and assembled using high-quality components from frames and circuit boards produced in close collaboration with China, to the aforementioned belts made in Germany, to Epson printheads and Sharp measuring and precision instruments. Over time, UV technology was joined by digital transfer technology (DTF), ideal for indirect printing on fabric and other materials: “In DFT”, Muredda proudly highlights, “Finitech has created Bravo-Dtf 603, the only that offers white, colour and fluorescent colour printing in one machine in one single step, thus meeting the fashion industry’s latest requirements.”

Although Finitech machine maintenance is simple, having been intentionally left open, another feather in the cap of the Treviso-based company is its after-sales service: among other things, this includes activating a WhatsApp service for advising customers not only on technical troubleshooting but also on other matters (even on offers) and lasts for the machine’s entire life cycle.