A professional screen printer must be mindful of both equipment and machinery, and the inks to be used. In fact, these must be selected taking into account the printing matrix and the drying

by Angelo Barzaghi, founder of and professor at Accademia Serigrafica

www.accademiaserigrafica.com

Depending on the target market, screen printing has its own language code, so to speak, and rules that govern it according to the processing cycle. More specifically: working for the textile and fashion industry has completely different goals and procedures from those that can be found in the graphics sector.

Let us make a quick distinction between the two sectors: the textile sector refers mainly to everything to do with the world of fabrics and, although we often think only of promotional clothing and off-the-rack fashion or, more narrowly, to t-shirts, cotton sweatshirts and shoppers, the world of textile screen printing also targets the design, automotive and furniture industry. In turn, this makes the approach to actual printing different, because, in addition to equipment and machinery, the criteria used to select inks must also change.

Matrix and fabrics

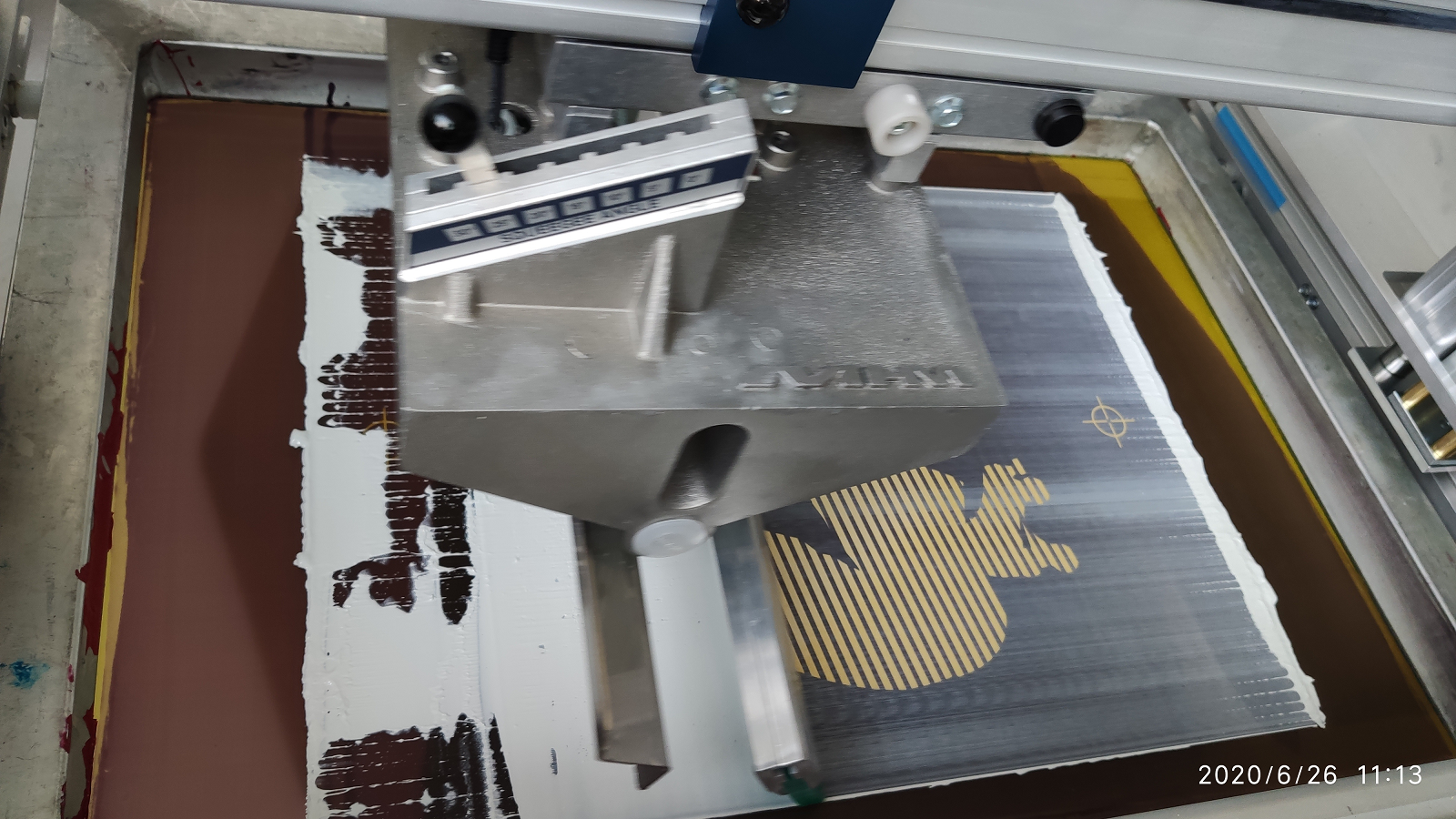

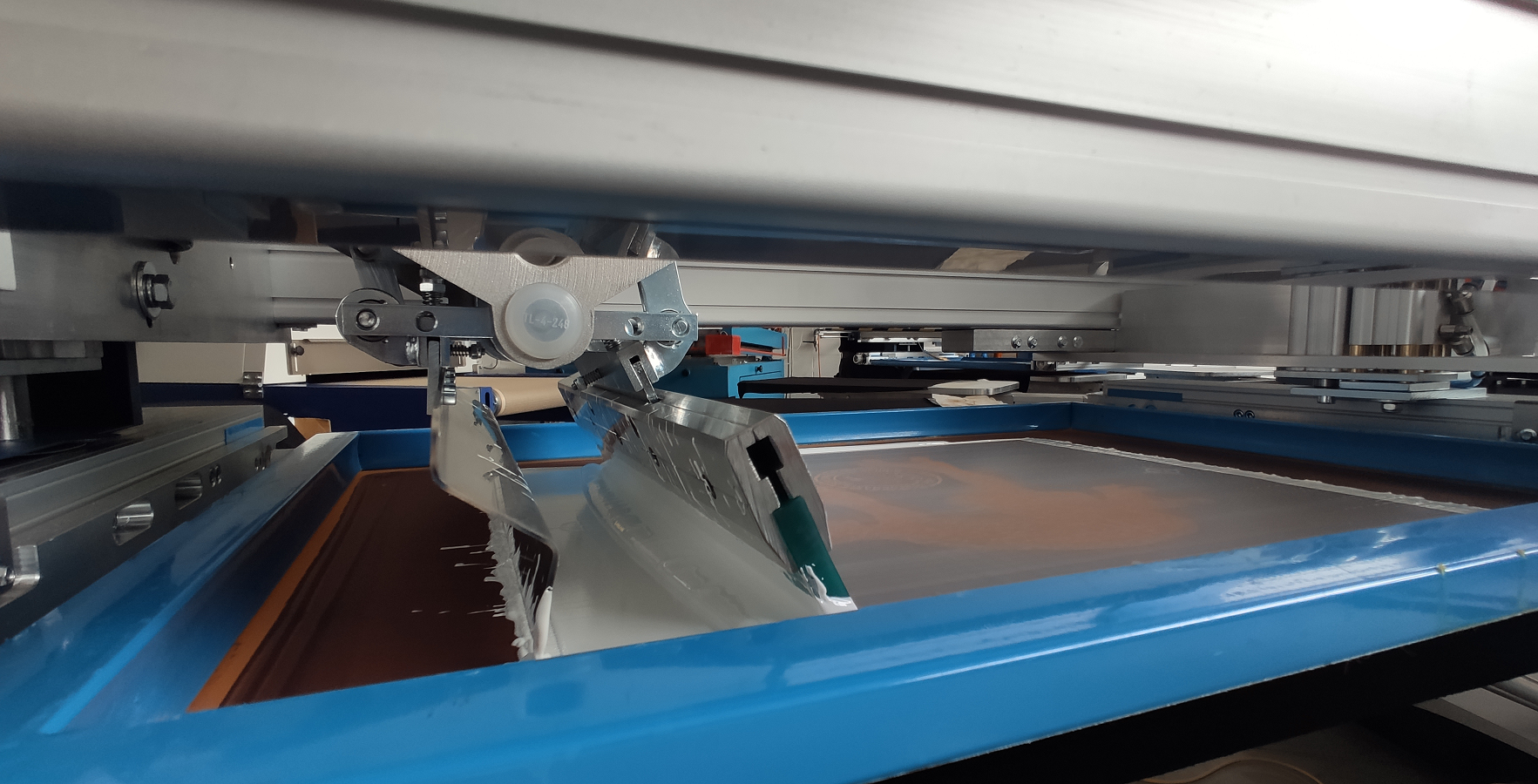

Screen printing inks are not all the same, but they do all have one fundamental characteristic in common: they must be suitable to pass through a matrix made of suitably processed fabric. We are talking about the screen printing frame and, if we are referring to professional screen printing, we have no option but to consider the printing matrix obtained using the conventional system.

In the various industries, inks often have dissimilar chemical and functional characteristics, while operating correctly on the same type of medium. For example, in the textile sector, this is the case with water, solvent, Plastisol or silicone-based inks. These inks work effectively on a very wide variety of natural and synthetic fabrics, and each has its own unique function and result. In the case of fibres such as polyester, for example, all these inks act very well and can also be used for various production requirements, although the coats and opaqueness will be different.

Pay attention to the drying process

We emphasize an important element: each ink has different drying requirements depending on its composition. UV or solvent-based inks are mainly used in the graphics industry; water-based products can also work well on certain specific surfaces. Also in this case the types of product require different drying systems depending on their nature.

As a result, inks must be selected first of all on the basis of the medium to be customised, taking into account both the production (printing machine and its accessories) structure and the type of oven or drying system available. Professional screen printing, therefore, cannot ignore the most appropriate choice of the final drying system to suit the ink used in the production cycle.